The built-in spring helps to maintain stable load, which enables consistent performance, while reducing

the need to adjust the Brush projection length frequently.

Lineup

|

Product code |

Target brush diameter

(mm) |

Diameter for the sleeve shank

(mm) |

Maximum rotational speed

(min⁻¹) |

Accessories |

Fig |

|

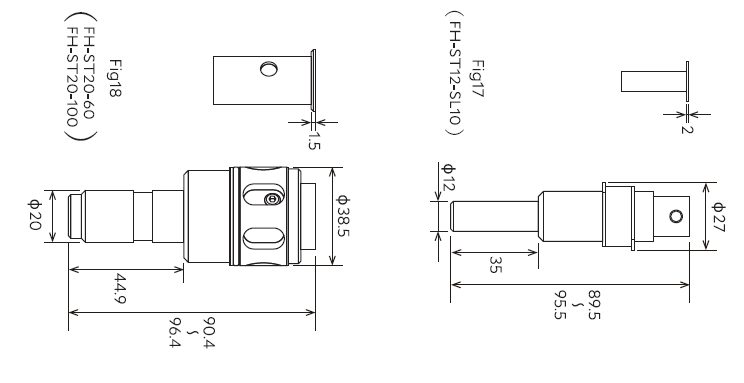

FH-ST12-SL10 |

φ6 |

φ6 (with the supplied bush ①) |

10000 |

①φ6 Bush

②φ8 Bush

③Low-pressure spring

④Standard spring*

⑤High-pressure spring

*Installed when shipped |

17 |

|

φ15 |

φ6 (with the supplied bush ①) |

6000 |

|

φ25 |

φ8 (with the supplied bush ②) |

5000 |

|

φ40 |

φ10 |

3000 |

|

FH-ST20-60 |

φ60 |

φ12 |

2000 |

φ12 bush |

18 |

|

FH-ST20-100 |

φ100 |

φ16 |

1200 |

φ16 bush |

18 |

FH-ST12-SL10

|

Spring type |

Outer diameter

(mm) |

Spring constant

(N/mm) |

Overall length

(mm) |

Load by stroke (N) |

|

0 mm |

6mm |

|

Standard spring |

Installed |

φ10 |

0.3 |

40 |

4.5 |

6.3 |

|

Low-pressure spring |

Attachment |

φ10 |

0.3 |

30 |

1.5 |

3.3 |

|

High-pressure spring |

Attachment |

φ10 |

0.55 |

39 |

7.2 |

10.5 |

|

Maximum load spring |

Sold separately |

φ10 |

3.03 |

30 |

15.2 |

33.4 |

Precautions for use

○ Apply the tool vertically when making it engaged with workpiece.

○ It can not be used if there are intermittent machining areas or protrusions.

○ In the case of horizontal machining center, telescopic function may not work if spring load is low.

Machine

Machine